New keypad interface and PC software

Supports: English, Chinese and Italian Languages

LCD panel, friendly human-machine interface easier

for commissioning and diagnostic.

Support parameter upload & download and remote control

|

Item |

Item specifications |

|

|

Voltage/frequency |

Rated output voltage |

3 phase:400V/480V(proportional to input voltage) |

|

Output frequency |

0Hz~400Hz |

|

|

Input voltage/frequency |

3 phase: 400V/480V;50Hz/60Hz |

|

|

Allowable voltage fluctuation |

voltage:340V~520V;voltage imbalance rate:<3%; |

|

|

Allowable frequency fluctuation |

Frequency imbalance rate:<±5% |

|

|

Running command channel |

Operator panel, control terminals, communications, and can switch by different ways, |

|

|

Frequency reference channel |

Digital, analog, communication, AUX-frequency, can switch over between these sources. |

|

|

Control mode |

Open-loop vector, close-loop vector, open VF, close VF, AFE |

|

|

Speed range |

1:200(open-loop vector),1:5000(close loop vector、servo) |

|

|

Start torque |

0Hz 150% rated torque(open loop vector),0Hz 200% rated torque(close loop vector) |

|

|

Frequency resolution |

Digital command: ±0.01%; analog command: maximum frequency× 0.2%Hz |

|

|

Running speed steady-state accuracy |

≤±0.5%rated sync speed(open loop vector), ≤±0.05%rated sync speed(close loop vector) |

|

|

Speed fluctuation |

≤±0.5%rated sync speed(open loop vector),≤±0.2%rated sync speed(close loop vector) |

|

|

Overload capacity |

G type:150%rated current for 2 minutes, 200% rated current for 0.5 second |

|

|

Torque boost |

Automatically or manually |

|

|

Speed up/down curve |

Line speed up/down, s-curve speed up/down; 4 speed up/down times, time unit(hour or minute), max 60 hours |

|

|

Automatic voltage regulator(AVR) |

Automatically maintain a constant output voltage when the input line voltage changes |

|

|

Protections |

Overload, over current, over voltage, short-circuit, speed loss, over temperature etc. |

|

|

Built-in Function |

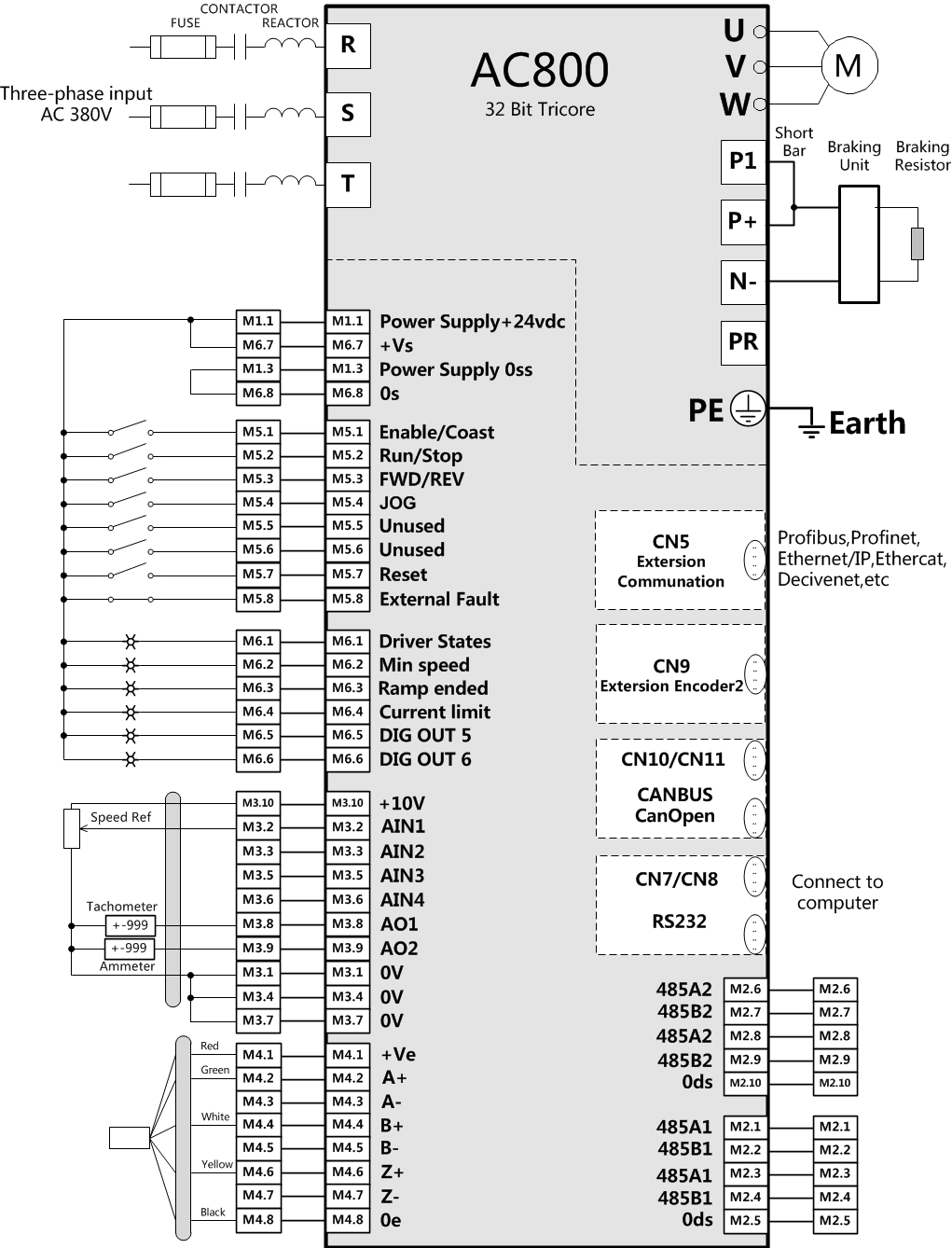

Multi-function input |

Include 8 digital input terminals (DI1-DI8), can achieve: drive enable, speed enable, differential input enable, analog input enable, jog enable, torque enable, AUX-PID enable, motor-driven potentiometer, 2 motor parameters option, external fault etc. |

|

Multi-function output |

Include 6 digital output terminals (DO1-DO6), can achieve: drive ok, fault indication, running indication, frequency detection, minimum speed indication, drive overload, speed up/down finish, overcurrent indication, internal comparator output etc. |

|

|

Built-in function blocks |

Built-in lots of function block: separate setting multiply/divide blocks, differential block, normalize block, speed-position conversion block, switch block, summation block, absolute block, minimum speed block, slack-tackup block, digital potentiometer block, comparator block, non-linear gain block, digital filter block, Aux-PID block, float block. |

|

|

Operator/Display |

LCD panel |

128*64 dot matrix LCD display, Chinese/English language option |

|

Parameters copy function |

||

|

Setting frequency reference quickly, local or remote mode. |

||

|

Plug and play |

||

|

PC monitor |

Both Chinese and English PC software, powerful oscilloscope function, multi-channel data recording and waveform display. Support parameter copy and download. |

|

|

|

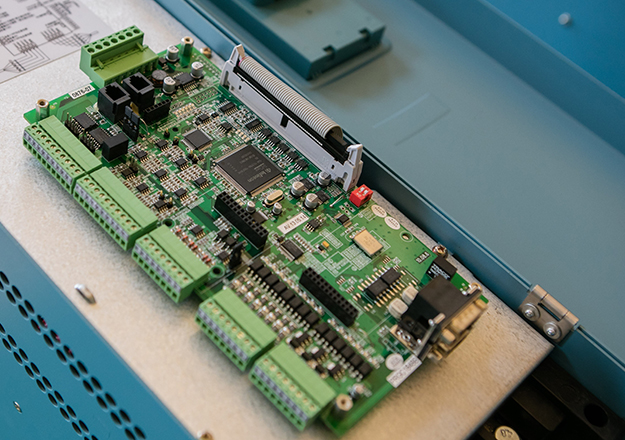

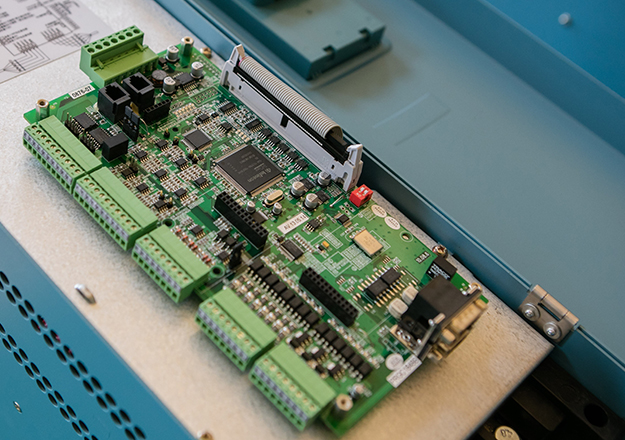

Communication Functions |

Powerful network communication capability, built-in 2 RS485 series interface (standard Modbus protocol), support external optional profi-bus, device-net interface card, 2 built-in Can bus interface (support Can-open protocol). |

|

Expansion Function |

Communication |

support external optional profibus, device-net interface card |

|

Encoder |

Built-in one standard encoder feedback interface, support another external optional encoder feedback card. |

|

|

Analog |

Built-in four 0-10V analog inputs and two 0-10V analog outputs; By expansion card, can achieve two 0-20mA (or 4-20mA) analog input channels, and two 0-20mA (or4-20mA) analog output channels. |

|

|

Relay output |

2 groups of expansive relay output, each include 1 NC and 1NO contact. Electrical specification: AC250V/2.5A,DC24V/5A |

|

|

External 24V control power |

When main power supply is disconnected to AC800, customer can input an external 24V control power supply to M1 terminal to power on AC800 control board and LCD panel. After control parameters are set and tested correctly, switch the main power on and run the motor. This is more convenient and safe for customers. However, our standard version has no this function. If this function is required, need optional expansion board. Refer to F2,7. |

|

|

Safe torque off (STO) |

Through expansion boards, AC800 can have 2 separated STO control channels in hardware circuits. Any one is not shielded, torque is safely turned off. The STO function is implemented in hardware; it overrides all software activities. The only software involvement is to report STO status to user via an MMI, series interface or user terminal on the AC800 STO expansion board. Refer to F2.7. |

|

|

Active front end AFE |

Detect synchronous signal AFE function need. AT AC800 AFE control mode, can achieve a PWM rectifier or a grid tie inverter with nearly 1.0 power factor and input perfect non-harmonic sine current. |

|

|

Environment |

Power line length |

Less than 100m |

|

Wiring terminal |

Main power terminal: standard; control terminals:pluggable |

|

|

Installation location |

Indoor, free from sunlight, dust, corrosive gas, combustible gas, oil smoke, vapor, drip or salt. |

|

|

Altitude |

Less than 1000m, de-rated when higher than 1000m, 10% per 1000m |

|

|

Ambient temperature |

-10℃~+40℃(de-rated when used in 40℃~50℃,) |

|

|

Humidity |

5%~95%RH, no dew and no hydrosphere |

|

|

Vibration |

Less than5.9m/s2 (0.6g) |

|

|

Storage temperature |

-40℃~+70℃ |

|

|

Pollution degree |

PD2 |

|

|

Power distribution |

TN,TT |

|

|

|

IP level |

IP20 |

|

Cooling type |

Forced air cooling,DC fan |

|

|

Brake Unit |

Built-in brake unit for 15kW and below power size; optional for above 15kW size. |

|

|

Installation Type |

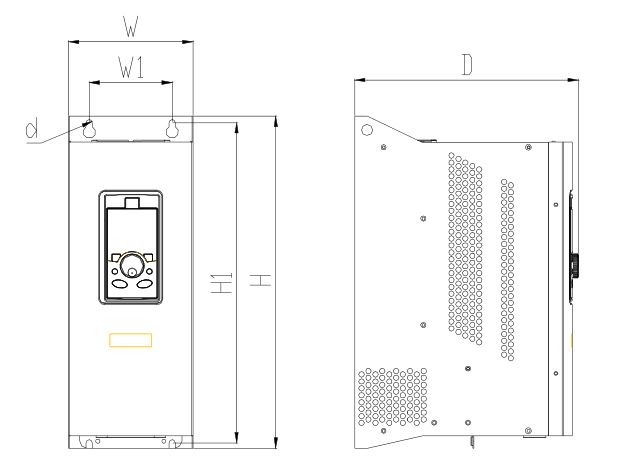

Wall hanging type, hanging or cabinet type for above 110kW |

|

|

Efficiency |

≥93% for <=45kW power size;≥95% for >=55kW power size |

|

▲To zoom in, right click to save the picture.